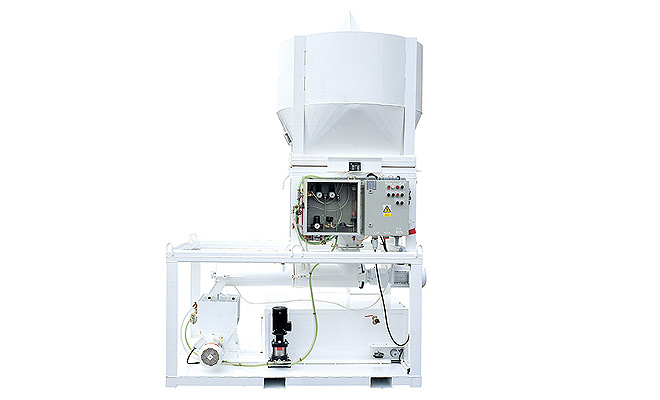

MPCS 3

Tundish spraying machine

Long-term expertise in the metallurgic industry is reflected in the metallurgic plastering machine MPCS 3, which is an ideal solution for the preparation and conveyance

of refractory magnesite plasters, and their application to steel-making ladle walls.

The machine is designed for processing big-bag mixes, and its sophisticated aerator system guarantees trouble-free conveyance of the mixture to a continual mixer. The continual water flow meter assures stable consistency of the plaster mix upon its entry into the pump, while the smart design enables visual inspection of the consistency

by an operator. Use of pneumatic remote control delivers maximum comfort and

independence of an operator. The MPCS 3 is a reliable machine, which is fine-tuned for a wide range of applications with different refractory plaster mixes.

Parametry

| Technical specification | Dimensions | ||

| Engine power | transport height | 1970 mm | |

| mixer | 5,5 kW | filling height | 3570 mm |

| pump | 5,5 kW | Width | 1700 mm |

| water pump | 0,75 kW | Lenght | 2250 mm |

| vibrator | 0,18 | ||

| Heater output | 3x800 W | Weigt | 1700 kg |

| Operating voltage | 400 V, 50 Hz | ||

| Voltage system | TN-S 230/400V, 50 Hz | ||

| Control voltage | 24 V, 50 Hz | ||

| Hopper cappacity | 2,5 m3 | ||

| Total input power | 30,4 A | ||

| Technical performance of the mixer | 3,6 m3/hod. | ||

| Type of spindle pump | standard D5 | ||

| Technical performance of the pump | standard 2,4m3/hod. | ||

| Conveying distance | max.40 m | ||

| Conveying ducting pressure | max. 3,0 MPa |

Accessories

| Conveying hose DN 25 á 15 m | 1 pcs |

| Air hose á 15 m | 1 pcs |

| Platering gun | 1 pcs |

| Remote control | 1 pcs |

| Cleaning hose | 1 pcs |

| Flexible cable | 1 pcs |

| Water hose | 1 pcs |

| Seal MDR 25 | 2 pcs |

| Air hose | 1 pcs |

| Cleaning tool DN 25 | 2 pcs |

| One side key 24 | 1 pcs |

| Greasing tool 125 | 1 pcs |

| Stator D 5 | 4 pcs |

| Rotor D 5 | 4 pcs |

| Power cable | 1 pcs |

| Test manometer | 1 pcs |