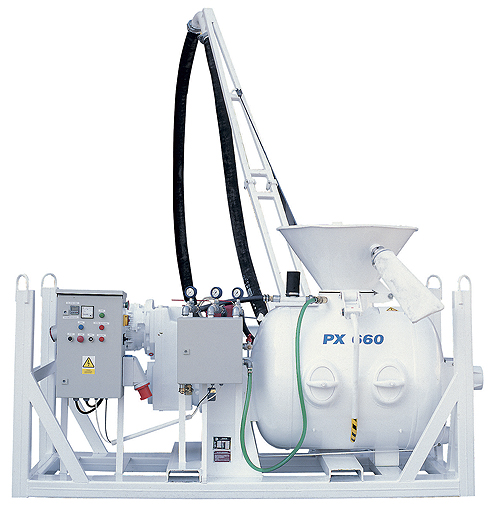

PX 660

Pneumatic conveyor

The pump PNEUMIX PX 660 is manufactured according to the newest technical knowledge’s from the sphere of construction and safety of the operators and it is the next of the successful line of the products of Strojstav Company. It is dedicated for the manufacturing and conveying of solid and moistened concrete mixture and refractory concretes. It is suitable for the using in the metallurgical industry at the production of the raw iron for the concreting of the canals and outflows, at the production of steel for concreting of the steel-works pans, hoods, and so on. The machine can be used also in the building (construction) industry at the concreting of base of building, floors and larger concreted areas.

Its structure and the location of single components allow performing the comfortable maintenance and repairs and also contribute to the general reliability of the machine.

The standard mixing and conveyance performance is cca. 10m3/hour.

The pump is feeded by the crane, with the mixture supplied in the high-volume bags called big-bag.

The correct volume of water is supplied by the electronically water doser.

Dosed mixture is mixed by the mixing blades. The correct mixing of the mixture is indicated by the ampere-meter placed on the control-box, where the off take of the el. motor is lowered at the mixed mixture. Mixture closed in the pressure tank will be aired by motion of blades and by the compressed air „upper air„. Blades slide simultaneously the mixture and dose it into the delivery branch of the tank. Additional „lower air I„ entering into the delivery branch slides farther ejected mixture, so begins the uniform motion of mixture in transport hoses. Transport of the mixture passes in agglomerates. To avoid the mixture is returning back to the vessel, the machine is equipped by the so-called „QUESTCH“ valve (Squeeze-valve), which is closing the vessel hub. The mixture is replaced form hoses by the additional „lower air II“, which is leaded beyond this valve.

To make the concreting of the hoods or canals easier, the machine is equipped with the assistant turning arm, the hight of this arm is adjustable by the hand-winch.

The control box is equipped with the block of restarting, it means that after the blackout that causes the stopping of the machine, it is necessary to start the machine again (after the elimination of the machine stopping) with the green button „START“. Because of the prevention, the machine is equipped with the button „CENTRAL STOP“ which is dedicated to disconnect the whole machine from the power supply. After using this button it is necessary to re-string the main breaker inside the control box.

All electrical elements are located in the water resistant and dust resistant case fixed at the frame. Its location allows the easy access to all controlling items and sockets.

Parametry

| Technical specification | Dimensions | ||

| Mixer vessel volume | 660 l | Height | 1850 mm |

| Refill | 0,75 t | Width | 1400 mm |

| Output | 10 m3/h | Lenght | 2880 mm |

| Delivery distance | Weight | 1740 kg | |

| - horizontally | 100 m | ||

| - vertikally | 40 m | ||

| E-motor | 22 kW |

Accessories

| Conveying hose DN 100 L= 4,5 m | 1 pcs |

| Conveying hose DN 100 = 4,5 m | 1 pcs |

| Cleaning tool DN 120 | 2 pcs |

| Power cable L=20 м | 1 pcs |

| Coupling of hose DN 100 | 3 pcs |

| Key of electric distribution box | 1 pcs |

| Coupling GSK 19 | 1 pcs |

| Coupling SKG 19 | 1 pcs |

| Greasing tool 125 | 1 pcs |

| Air hose DN 19 L= 20m | 1 pcs |

| Water hose DN 19 L= 20m | 1 pcs |

| Cable | 1 pcs |